Copyright © Guangdong Huanyu Electronic Technology Co., Ltd. All Rights Reserved. Site Map

- 0086-20-34835808

- huanyutech@gdhuanyu.com

- No. 2, Maxing Street, Nansha District, Guangzhou City, Guangdong Province

Spring is not over yet, summer is coming, and the pace of improvement cannot stop.

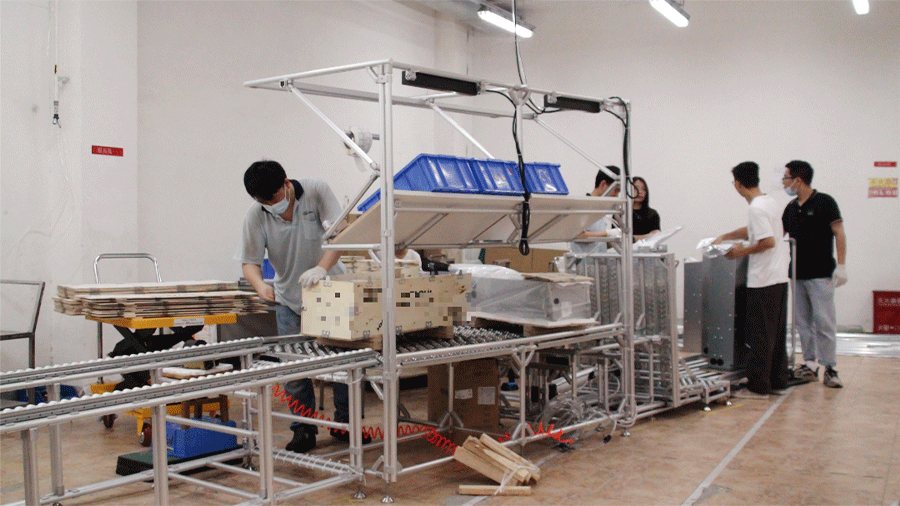

The second week of May ushered in the second lean improvement week. This improvement week carried out two improvement projects at the same time, namely ARD packaging unit design and warehouse design. The former focuses on improving UPPH (unit person-hour production capacity), and the latter focuses on saving floor space design. Please see the following introduction~

ARD Packaging Unit Design Project

Find waste points

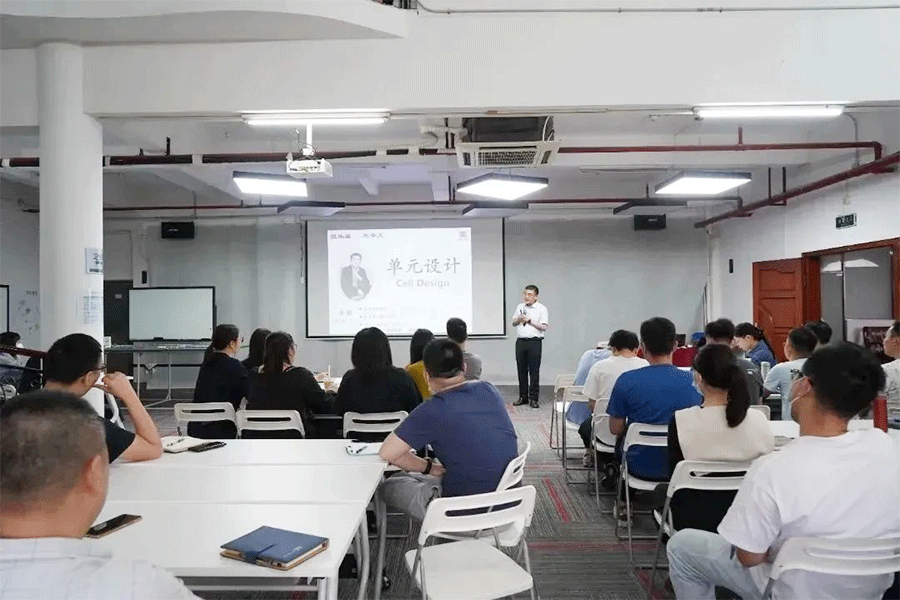

Unitization can fundamentally reduce waste. In order to find and collect waste as much as possible, students went to the site to watch and record the work of employees, and then watched the video again and again to analyze the movements.

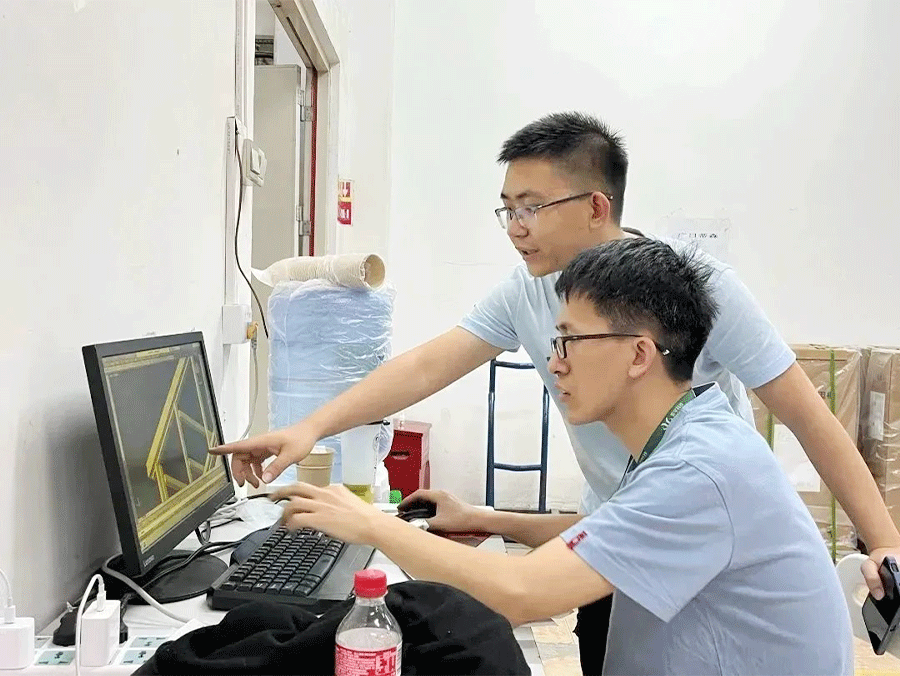

Solution output and review

Through observation and analysis, the students looked for areas for improvement and room for improvement. They produced a total of 5 solutions for competition.

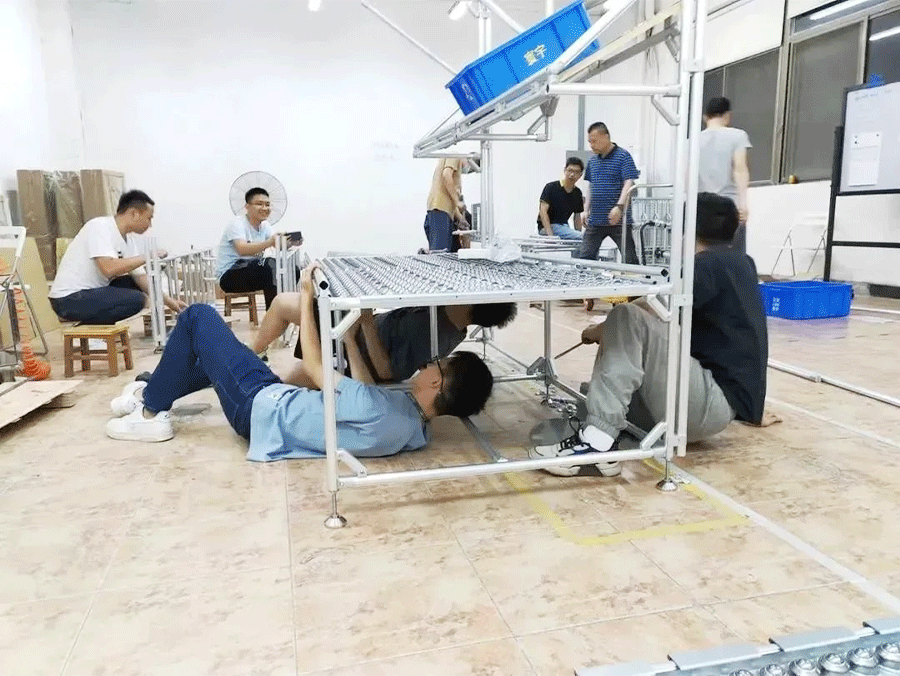

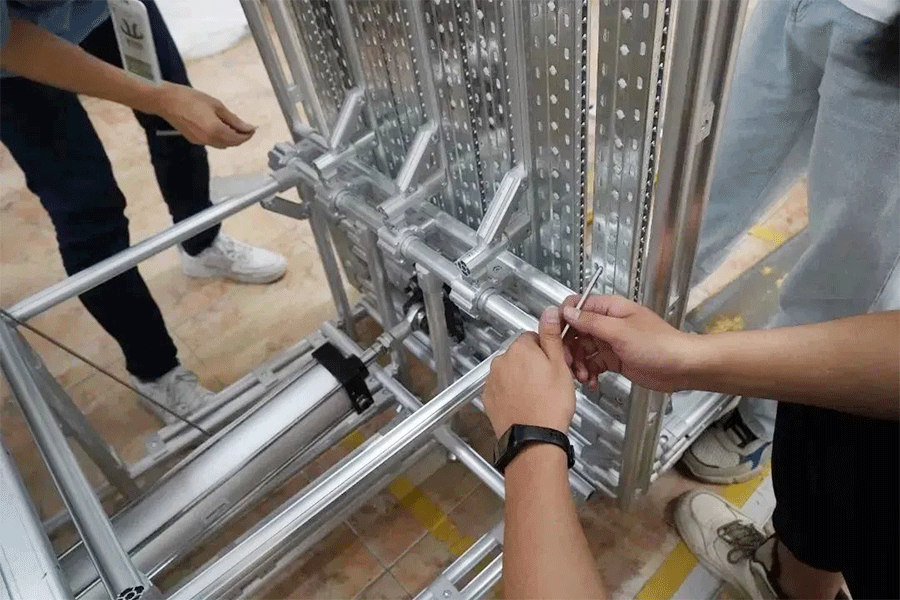

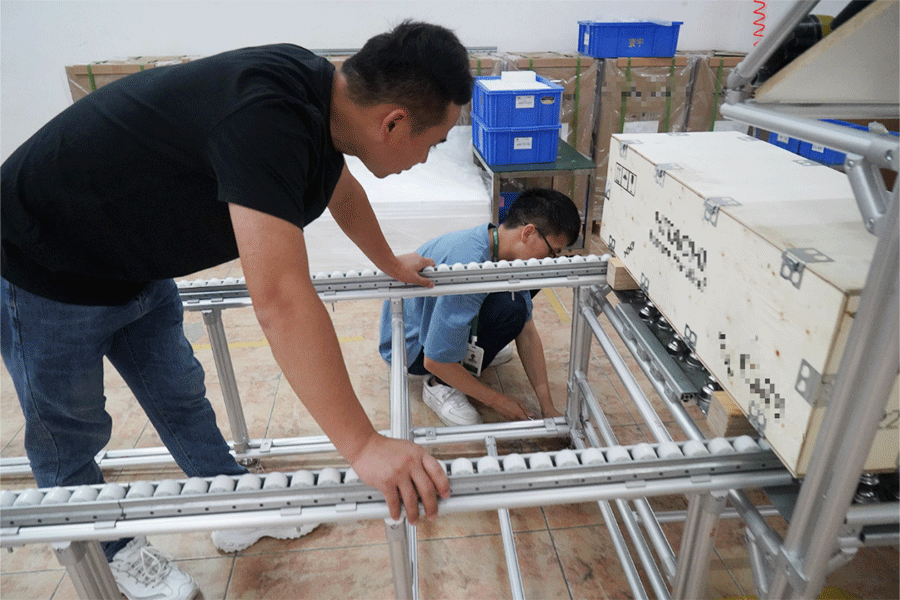

Preparation for line construction

Before the line was built, the packaging colleagues did not have a fixed workbench and needed to bend over frequently to operate. Everyone tried every means to solve the pain point of bending over and built a workbench.

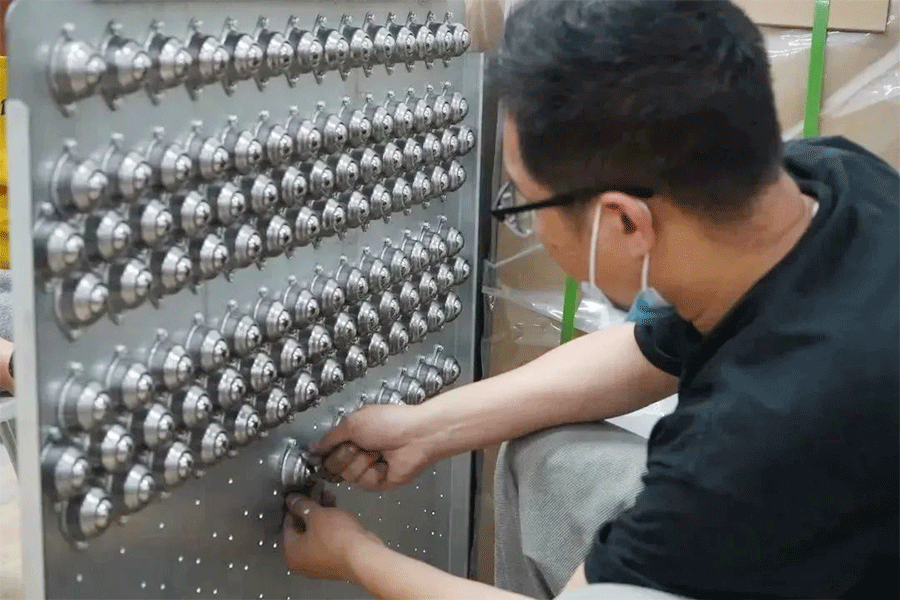

Production line test run

In addition to the commonly used lean tube and smooth strip tools, the workbench also introduces the design of universal wheels and flip tables.

Warehouse Design Improvement Project

Requirements collation and confirmation

In order to design a more comprehensive and reasonable solution, the students did a lot of information collection and collation work in the early stage. Including: storage restrictions, overall regional layout, basic material information, etc., and also discussed the principles of storage material planning.

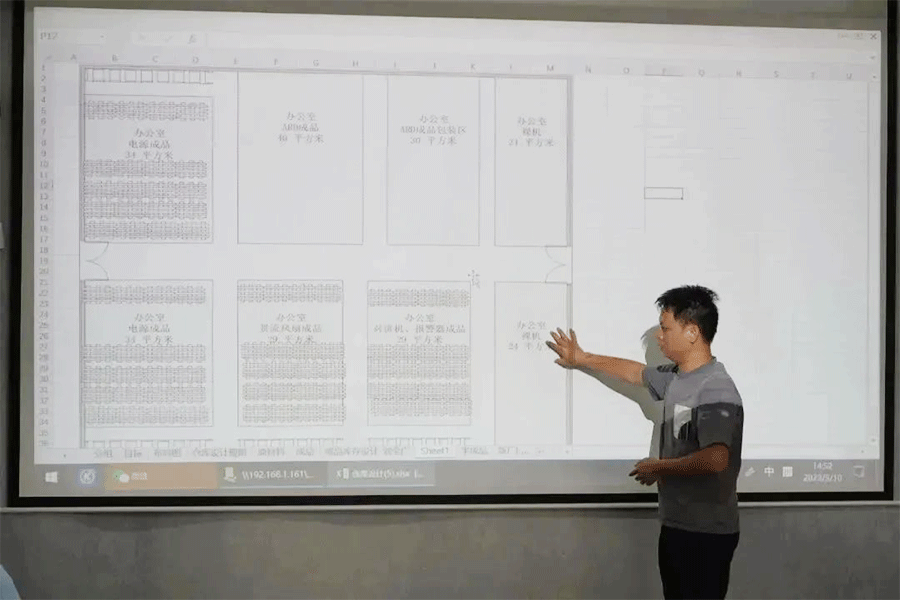

Group design

Each group will design the finished product warehouse, semi-finished product warehouse, and material warehouse areas respectively.

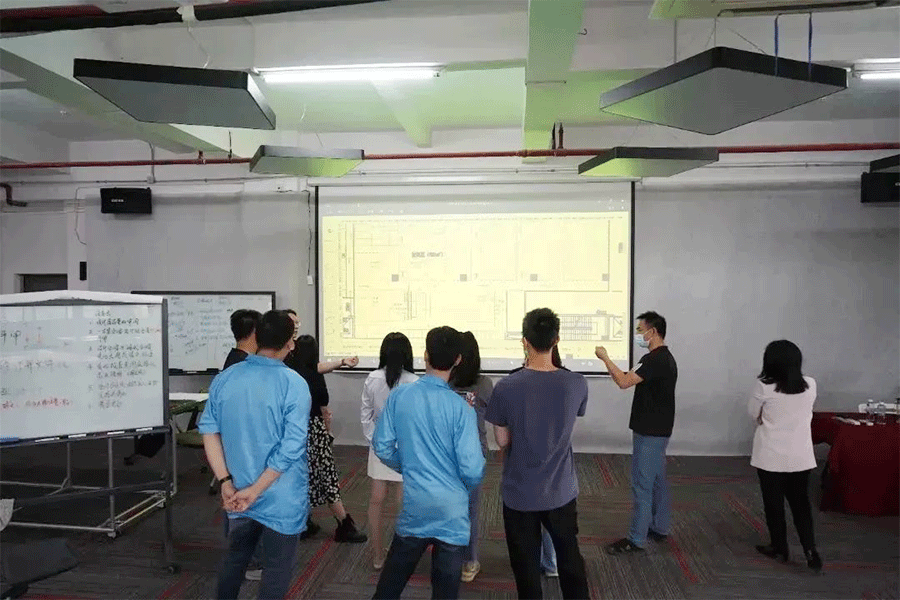

Plan Review

The rationality of the plan will be evaluated in combination with the corresponding container carriers of the regional design, stacking method, area requirements, sorting and zoning, channel design, handling methods, equipment requirements and other aspects.

Results Report

ARD packaging unit design project

1. UPPH improved by 43.39%, and can be operated by one or two people.

2. The floor space was reduced by up to 77.4%, from 78 square meters to 17.63 square meters.

3. Shorten the operation time, greatly reduce walking and waste.

4. Use universal wheels, turning tables, stripping machines, forklifts, etc. to reduce handling and turning actions, reduce labor intensity, reduce safety risks, and achieve simple automation.

Warehouse design improvement project

1. The storage area is expected to be reduced by 130%, and the efficiency per square meter is expected to increase by 350%.

2. Greatly shorten the logistics route, improve the first 8 material routes across floors, and reduce the number of materials that need to cross floors to 3 after improvement.